Hannover Messe 2024

CELEST at Hannover Messe 2024

The Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST) participates at the Hannover Messe from 22nd to 26th April 2024 as co-exhibitor at the Baden-Württemberg Pavilion in the Energy Solutions Area in hall 12, booth D15.

At the booth we present new battery materials, different cell types including round and pouch cells from ZSW and KIT Battery Technology Center and a fuel stack from ZSW. Furthermore we inform about our platform and the various activities including Innovation & Transfer, Qualification & Training and our communication channels.

Exhibits

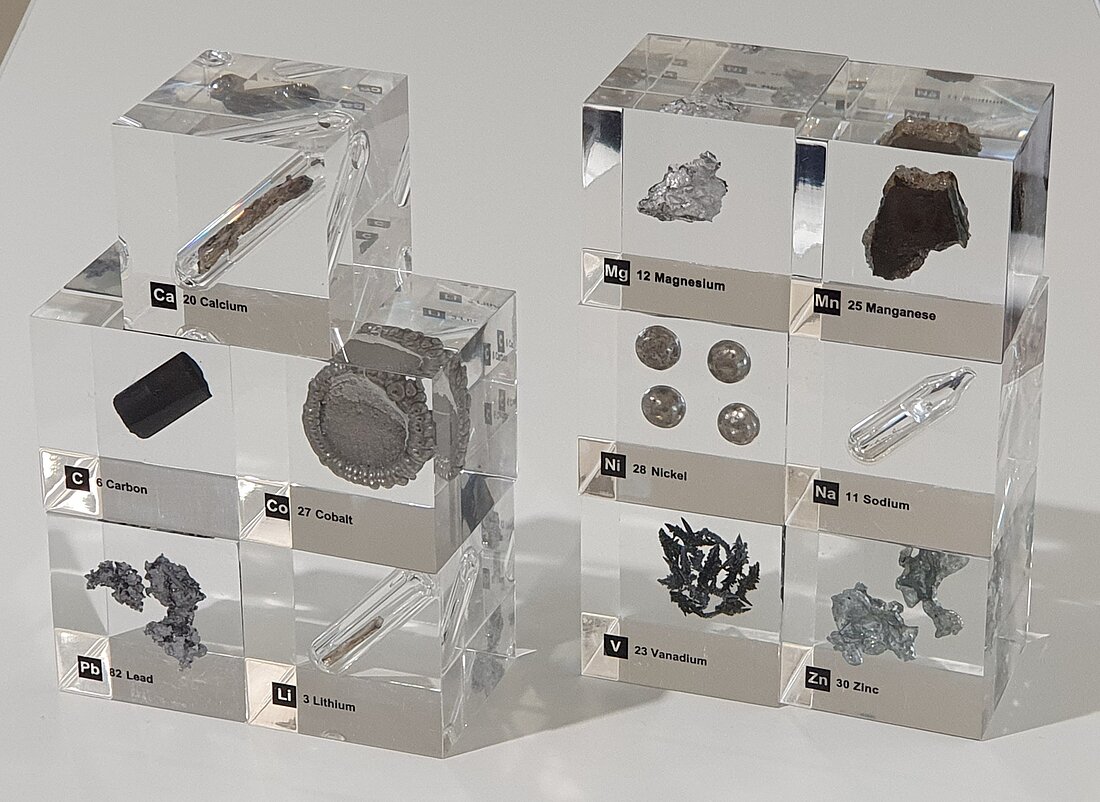

Cluster of Excellence POLiS - Batteries for a Sustainable Future

Batteries play a central role in the energy and transport revolution. The Cluster of Excellence POLiS (Post Lithium Storage) is embedded in the Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST) and one of the platform‘s main activities in the post-lithium area. In the Cluster, batteries of the future are being researched, batteries that are more powerful, reliable, sustainable and environmentally friendly than current lithium-ion batteries.

The Cluster aims at developing electrode materials and electrolytes that allow for sustainable systems based on Sodium, Magnesium, Calcium, Aluminium, and Clorine ions.

Click here for more information on the research activities in the Cluster of Excellence POLiS.

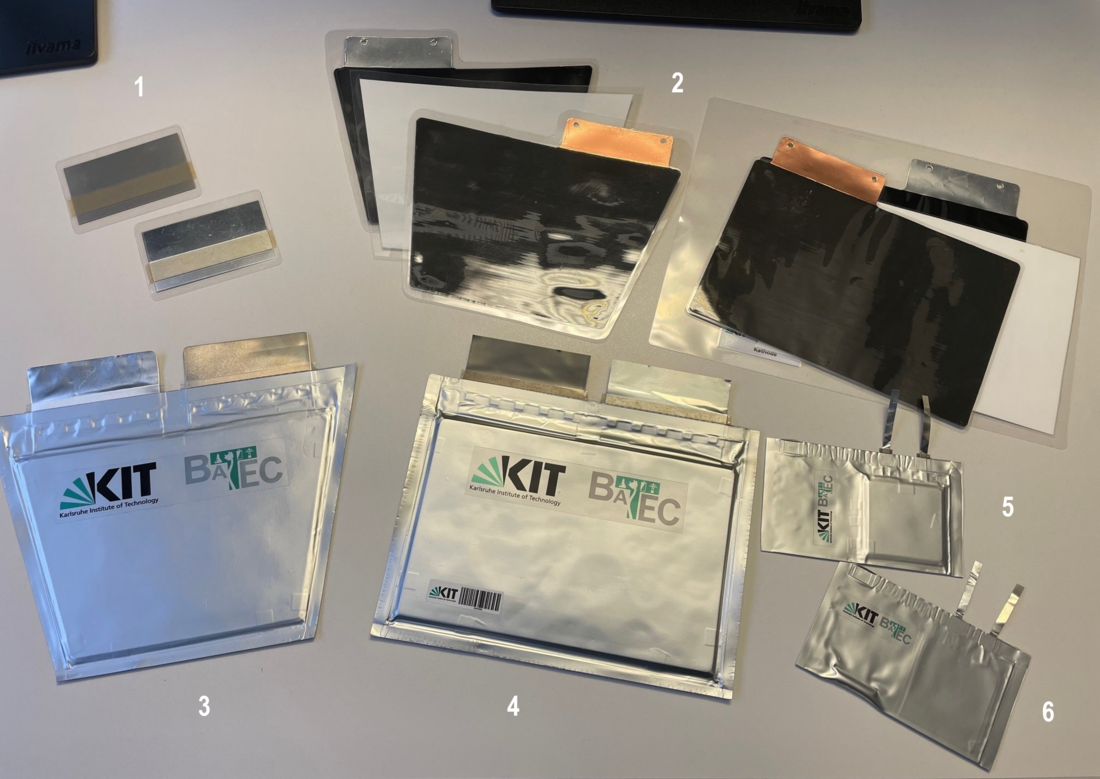

Cell Development and Testing at KIT Battery Technology Center

Generation, storage and use of electric energy on a sustainable and cost-efficient basis for stationary and mobile applications are among the biggest global challenges for the next decades. The research and development of innovative electrical energy storage systems is carried out in different institutes at KIT covering the entire value chain in a comprehensive, interdisciplinary approach. The objective is to develop industrially applicable, cost-efficient solutions for energy storage of the next generations.

The focus of cell development is on product-related research and development in lithium-ion cell technology with the objective to develop high quality and high performance cells. In cell testing, electrical cell characterization including long-term tests and application-oriented assessments can be carried out for the determination of cell performance.

For further information please visit:

Battery Technology Center: www.batterietechnikum.kit.edu

Work Group Cell Development: www.iam.kit.edu/ess

ZSW

ZSW

ZSW

ZSW

H2 and alternative storage

Fuel cells are among the enabling technologies toward a safe, reliable, and sustainable energy solution. Yet the lack of clean hydrogen sources and a sizable hydrogen infrastructure limits the fuel-cell applications today. Due to their elevated operating temperature, between 150°C and 180°C, high-temperature proton exchange membrane fuel cells (HT-PEMFCs) based on phosphoric acid doped polybenzimidazole (H3PO4/PBI) membranes can tolerate fuel contaminants such as carbon monoxide (CO) and hydrogen sulfide (H2S) without considerable performance loss. These are typical byproducts of the steam reforming process, which produces hydrogen from hydrocarbon fuels such as methanol or natural gas. So it is an appealing concept to couple a HT-PEMFC stack directly with a fuel processor, which can be used as auxiliary power units (APUs). These APUs use the fossil fuel resources more efficiently and help reduce emission of CO2. This might also be a good strategy for the wide deployment of fuel cells before the hydrogen infrastructure is established. The fuel cell system’s efficiency can be further increased by reusing the exhaust heat produced during electrical power generation.

The slow oxygen reduction reaction in concentrated phosphoric acid remains a major technological challenge for future development of HT-PEMFCs. The slow reaction rate is believed to be related to strong adsorption of phosphoric acid species on the surface of the platinum catalyst. It is generally accepted that adsorption of molecular or anionic species from the concentrated phosphoric acid electrolyte hinders ORR by blocking active sites on the catalyst surface. To gain a better understanding of the adsorption mechanisms we conduct systematic studies employing various types of perfluoroalkylated derivatives of phosphoric acid. We evaluated these model electrolytes for their adsorption behavior and influence on ORR on a polycrystalline platinum surface.

The Zentrum für Sonnenenergie-und Wasserstoff-Forschung Baden-Württemberg (ZSW) is one of the leading institutes for applied research in the areas of photovoltaics, battery technology, fuel cells, renewable fuels, and energy system analysis. The Ulm- site focuses on batteries and fuel cells development as well as Hydrogen technologies. The work covers the full value chain from materials to systems including testing and recycling. This also includes modelling and simulation of electrochemical processes, synthesis and characterization of innovative materials, components optimization and their pilot production. New products are qualified and tested as demonstrators in the field. Working very closely with industry, research institutes and universities, we take an application-minded approach to R&D.

New generations of batteries are typically introduced every two years, driven by rapid advances in development, optimization, and production processes. This continuous progress enables continuous cost reduction while increasing performance. In addition, there are growing concerns about the availability of critical raw materials and the reduction of the environmental footprint. ZSW works in both fields and is committed to maintaining close collaboration with the industry and remaining at the forefront. ZSW previously systematically upgraded and expanded its manufacturing facilities, particularly for assembling pouch and PHEV2 cells up to 80Ah and round cells up to 46,800Ah. This expansion was successfully completed by the end of 2023.

Further information on ZSW can be found here.

Information on activites on H2 (focus on safety aspect) at KIT can be found here.

Further CELEST Topics

Technology transfer promotes communication and networking, thus ensuring greater transparency and knowledge exchange and acting as an interface to industrial research and development. The continuous expansion of the battery network, which works closely with POLiS researchers, is intended to contribute to innovative ideas and demand- and application-oriented research at an early stage. Technology transfer is promoted by the following measures:

- Industry workshops such as "Emerging Technologies - From Research to Manufacturing" and "New Generations - Batteries and Talents"

- Creation of an innovation map - a database was compiled featuring a wide range of property rights for novel material and process developments

- Participation and presentation at conferences and trade fairs

- Development and operation of a research plant infrastructure for battery cell production at various scaling levels from manual laboratory cell production to a fully automated pilot line

- Supporting researchers with spin-offs

Patent Highlights

Lithium-ion-conducting solid materials

Described are a solid material which has ionic conductivity for lithium ions, a process for preparing said solid material, a use of said solid material as a solid electrolyte for an electrochemical cell, a solid structure selected from the group consisting of a cathode, an anode and a separator for an electrochemical cell comprising the solid material, and an electrochemical cell comprising such solid structure.

Patent-ID: WO2023111138A1

Coated particulate material for use in an electrode of an electrochemical cell

Described are a coated particulate material for use in an electrode of an electrochemical cell and a process for preparing said coated particulate material, an electrode comprising said coated particulate material for use in an electrochemical cell, an electrochemical cell comprising said coated particulate material, and a use of said coated particulate material for preparing an electrode for use in an electrochemical cell.

Patent-ID: WO2023099646A1

Device & method for compacting electrode material applied to a collector strip

A method for compacting electrode material applied to a collector strip is known. For this purpose, the electrode strip is guided in a conveying direction parallel to the longitudinal direction of the electrode strip through a compaction gap, which causes the electrode material to be compacted. At least one free region, in the region of which no electrode material is provided, is subjected to force in the longitudinal direction in order to thereby cause elongation of the collector strip in the free region in order to thereby compensate for elongation of the collector strip in the region of the electrode material caused by the compaction. It is proposed that the elongation of the collector strip in the at least one free area is effected in the longitudinal direction by the collector strip being subjected to force in the conveying direction behind the compaction gap by means of at least one conveyor roller acting on the free area and at the same time being held back in the conveying direction in front of the compaction gap by a braking device acting on the free area, so that the collector belt in the free region between the braking device and the conveying device is subjected to tensile stress, thereby causing plastic elongation in the longitudinal direction in the free region.

Patent-ID: EP4016664A1

Propagation barrier having reinforcing filler material & method for the production thereof

The present invention relates to a barrier for preventing propagation of a thermal event within a multi-cell battery module (referred to as "propagation barrier") which comprises a heat-absorbing protective layer based on a hydrogel and a reinforcing filler material. The invention further relates to a battery module which comprises the barrier and to the use of the barrier for compensating volume fluctuations within a battery module. In addition, the invention relates to a method for producing the propagation barrier.

Patent-ID: WO2023094666A1

Process for making a coated cathode active material, and coated cathode active material

Process for making a coated electrode active material wherein said process comprises the following steps: (a) providing an electrode active material according to general formula Li1+xTM1-xO2, wherein TM is Ni or a combination of Ni and at least one of Co and Mn, and, optionally, at least one metal selected from Al, Mg, Ti and Zr, and x is in the range of from zero to 0.2, (b) contacting said electrode active material with a solution of salts of M2 wherein M2 is a combination of metals that includes Co, Cu, Ni, Zn and Mg, at a temperature in the range of from 5°C to 85°C, (c) removing the solvent from step (b), thereby obtaining a solid residue, (d) exposing the solid residue from step (c) to 3 to 10 pulses of electromagnetic radiation with a wavelength in the range of from 200 to 1400 nm, wherein the duration of the pulses is in the range of from 1 milliseconds to 2 seconds, (e) heat-treating the material so obtained in an oxygen-containing atmosphere at a temperature in the range of from 300 to 750 °C for 10 minutes to 4 hours.

Patent-ID: WO2023280534A1

Skilled scientists and engineers are key for further development and implementation of electrochemical energy storage. Within CELEST, comprehensive teaching to doctoral researches in this field is offerd by two insitutions: The Graduate School Electrochemical Energy Storage (GS-EES) and the research training group Simulation of Mechanical-Electrical Thermal Processes in Li-ion Batteries (SiMET).

The GS-EES supports almost 90 doctoral researchers at Karlsruhe Institute of Technology (KIT), Ulm University and Justus-Liebig-University Giessen and is the largest graduate school in Germany in the field of electrochemical energy storage. It addresses the full interdisciplinary spectrum of electrochemical energy storage and conversion, from fundamental science to processing and application. Among the topics are Lithium-ion batteries, post Lithium batteries and fuel cells.

Highlights of the GS-EES training and support measures are:

- Three-month research stay abroad

- Two weeks of interdisciplinary Block Course “Materials, Functioning and Technology of Batteries”

- Annual Summer School

- Broad portfolio of workshops on scientific or method-related topics and on professional skills

Communicating scientific topics to the general public is also a major topic within the framework of CELEST. Especially the two podcasts, one German- and one English-language podcast, are very successful tools when it comes to making scientific topics understandable for the general public. Additionally, news are spread via several LinkedIn pages and the platform X.

GELADEN - Der Batteriepodcast

GELADEN - Der Batteriepodcast is a German-language podcast launched in 2020. In addition to the audio podcast, there is also a video interview published on YouTube. Every Sunday, the hosts Patrick von Rosen and Daniel Messling talk to researchers and experts about electromobility, the energy transition and battery research. With over 4.6 million downloads, GELADEN is the #1 chemistry podcast in Germany. The podcast is produced by the Helmholtz Institute Ulm (HIU), the Cluster of Excellence Post-Lithium-Storage (POLiS) and CELEST, the Center for Electrochemical Energy Storage Ulm & Karlsruhe | Ulm & Karlsruhe.

Battery Generation

Battery Generation is an English-language podcast and Europe’s #1 Battery Podcast for Electromobility and Electrochemical Energy Storage. We are on a mission to find batteries that are powerful, safe, sustainable, long-living, as light and small as possible, cheap and easy to recycle. Is that even possible? The hosts Patrick von Rosen and Lennart Peters are talking to leading experts and scientists working in the battery field. The podcast is produced by the Helmholtz Institute Ulm (HIU) and CELEST, the Center for Electrochemical Energy Storage Ulm & Karlsruhe.